Quality management systemQuality management system

In order to ensure the reliable quality of the Shimomura brand, we have established comprehensive management systems. In addition to rigorous quality checks during each manufacturing process, we have the full range of high-precision inspection equipment. These systems ensure quality from every aspect.

Identification Technology Promises Peace of Mind

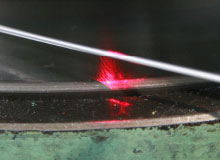

Spark inspection (SCM435)

Spark inspection (SUS 420J2)

A grinder is used on the steel material to generate sparks; the material can be identified by the color and shape of the sparks.

Materials Sorting

EC equipment and sorting devices are installed in-line. Materials identification is reinforced by irregularity and defect detection.

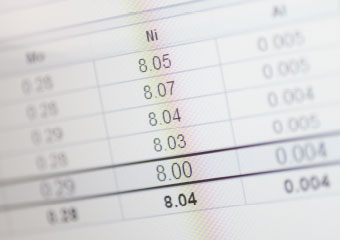

X-ray analysis

X-ray analysis equipment was introduced and composition analysis is performed to enhance material identification.

Emission spectroscopy analysis

In addition to material identification through irregularity detecting and X-ray analysis, emission spectroscopy analysis further enhances identification.

Defect Detection System Ensures Safety

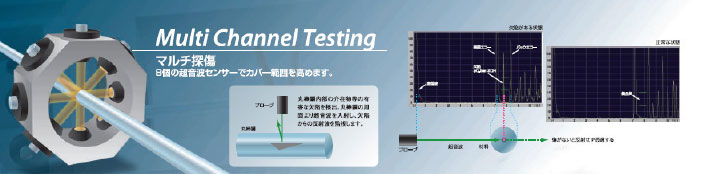

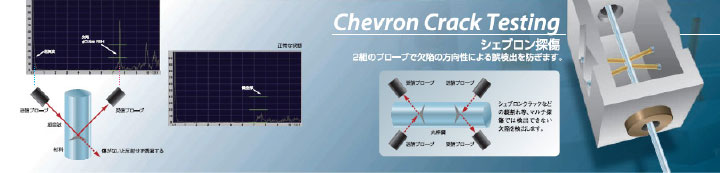

Ultrasonic testing equipment (UT)

Ultrasonic testing detects defects inside products.

Provided by KJTD Co., Ltd.

Vertical: SDH ϕ 0.5 × 10 mm or more; angled: FBH ϕ 0.5 or more

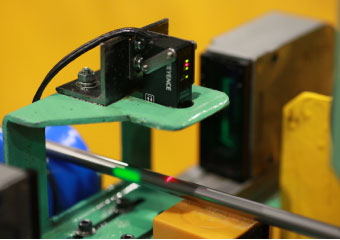

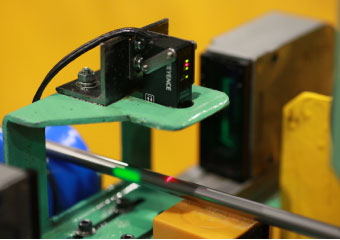

Eddy current flaw detection device (EC)

Detects flaws in the surfaces of products.

EC Rotating Format

EC Pass-Through Format

Figures courtesy of Foerster Japan Limited

Defect depth: 0.1 mm × Defect length: 10 mm

Internally-Developed Quality Management Equipment

CG Circularity Monitoring Device

Circularity measurements are performed within the CG line, enabling defects to be detected at an early stage.

WD Localized Bending Detector

Detects localized bending of coils in the WD line, enabling defects to be detected at an early stage.

CM Localized Tapering Detector

Localized tapering is detected in the CM line, preventing release of defective products.

Enhanced High-Performance Inspection Equipment

High-Straightness Products

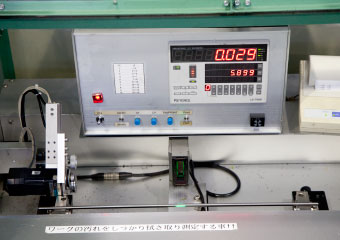

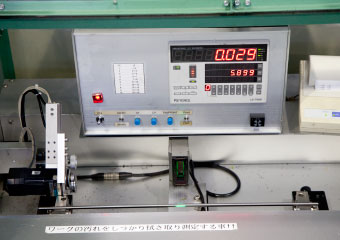

Short-distance deflection tester

Shimomura has the technological levels to support rigorous straightness requirements.

Quality examples

φ7 ≦0.02 mm/150 mm

φ5 ≦0.02 mm/255 mm

φ3 ≦0.01 mm/50 mm

Automatic cylindricity measuring instrument

Shimomura products have the technological levels to support cylindricity requirements that are stricter than standards (one-half of tolerance).

Quality example

φ10 (0,-10) ≦4μm

High Circularity Products

Circularity measuring instrument

Shimomura products have the technological levels to support circularity requirements that are stricter than standards (one-third of tolerance).

Quality example

φ6 (+6,+2) ≦1.3μm

High-Precision Control of Surface Roughness of Grinding Products

Surface roughness measuring instrument

Shimomura products have the technological levels to support surface roughness requirements that are stricter than standards (Ry≦3.2μm).

Quality example

φ2 Ry≦1.6μm

Narrow Tolerance Products

Dimension measuring instrument

Drawn products have the technological levels to comply with tolerance requirements that are stricter than standards (h9).

Quality example

φ10 0.010 mm / φ1 0.010 mm

Gliding products have the technological levels to comply with tolerance requirements that are stricter than standards (h7).

Quality example

φ6 0.004 mm

Circularity measurements are performed within the CG line, enabling defects to be detected at an early stage.

Circularity measurements are performed within the CG line, enabling defects to be detected at an early stage. Detects localized bending of coils in the WD line, enabling defects to be detected at an early stage.

Detects localized bending of coils in the WD line, enabling defects to be detected at an early stage. Localized tapering is detected in the CM line, preventing release of defective products.

Localized tapering is detected in the CM line, preventing release of defective products.